PreEngineered Metal Buildings Construction Company Facility Development Company

PreEngineered Metal Buildings Construction Company Facility Development Company

The complete construction process of a pre-engineered steel building involves 3 major stages which are designing, fabricating and installing at construction sites. Advantages of pre-engineered steel buildings

Pre Engineered Steel Buildings (PEB) Memaar Building Systems

Although the name pre-engineered metal building "kit" may sound like a cookie-cutter, assembly-line product, there are endless ways to design a Metal Building. provide the quick construction and cost-savings you would expect in a "kit," but come with unlimited possibilities for customization. How Do Metal Building Systems Work

Pre Engineered Steel Building, प्री इंजीनियर्ड स्टील बिल्डिंग, पूर्व अभियांत्रिकी इस्पात इमारत

Solutions Customized Hybrid SolutionsBuild without limits! Hybrid designs combine pre-engineered & conventional steel for high-performance structures. Buildings Under 5K SFOur platform offers instant pricing, shorter lead times & self-checkout.

Pin on Organic Posts

The Ultimate Guide. Pre-Engineered Metal Buildings (PEMB) These structures have been growing in popularity for many reasons. They are cheaper and faster to construct than traditional building methods, they are more durable and require less maintenance, and they can be used for various applications.

Image result for pre engineered metal building expressed structure Pre engineered metal

The design analysis of the PEB frame is been carried out through plastic analysis and the validation is been done using Indian Standard codes. The obtained design section was analyzed in STAAD Pro software with the optimization of the sectional profile which reduces the steel quantity. Keywords. Pre-engineered buildings; Design analysis

Robertson Steel Buildings Preengineered Metal Buildings Canada Pre engineered metal

At Metal Design Build, we believe in honest, accurate pricing, custom designs, and real conversations with industry experts. We have 30 years of design and construction experience and offer the best pre-engineered metal buildings in the U.S. We partner with the industry's top fabricators and our compositions meet or exceed MBMA and AISC.

Pre Engineered Steel Buildings Nigeria Steel Building Manufacturers Nigeria

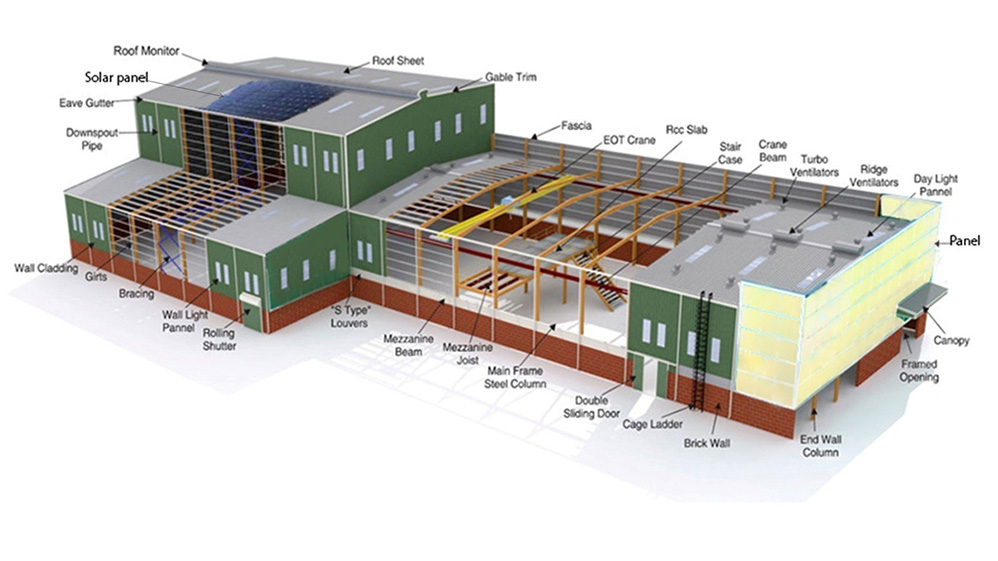

Pre-Engineered Steel Buildings are structures made of steel components that are designed and manufactured according to technical drawings at the factory, then transported to the site for assembly and completion. 1.2. Structure of Pre-Engineered Steel Buildings The structure of pre-engineered steel buildings includes the following main components:

6 Reasons to use a PreEngineered Building

Leading the industry in technology, design flexibility, longevity, and quality steel buildings for over three-quarters of a century, American Buildings is one of the nation's largest, most experienced manufacturers of custom metal building systems. American buildings are fully customized, energy efficient, environment-friendly solutions. With.

Prefab Metal Buildings Customize Your Metal Building Today

With 30' to the center of the building you will have gained 60" inches to the center of the peak When you divide that by 1 foot (12 inches) we see that we will have increased by a height of 5' feet. So a 60' wide building with a 10' eave and a 2:12 roof slope will have a peak of 15' where-as a 1:12 slope will have only added 2'6.

INTRODUCING READY MADE PREENGINEERED STEEL BUILDINGS FROM MRM (SAFBUILD) East African Modern

Primary frames are designed for full bay loading and span the width of a building. For the pre-engineered systems these primary members are typically I-beams. Frame systems include clear-span, multi-span and lean-to frames in tapered or straight format. Each steel frame system is custom engineered to meet specifications and local building codes.

What are Preengineered Buildings? Coverco Buildings

A pre-engineered building is a system utilizing three distinct product categories: Built-up "I" to shape primary structural framing members (columns and rafters) Cold-formed "Z" and "C" to shape secondary structural members (roof purlins, wall girts, and eave struts) Roll-formed sheeting profiles (roof and wall cladding). Aesthetic.

PreEngineered Buildings Introduction FUJI

Pre-engineered building review. Steel is an alternate building material because of its numerous advantages over reinforced cement concrete (RCC). This has led the entrepreneurs establish factories where the complete design and production is carried out at same place and the proposed structure is erected at site.. Pre-Engineered Building.

a large building under construction with lots of steel beams on it's roof and walls

A pre-engineered steel building is a modern technology where the complete designing is done at the factory and the building components are brought to the site in CKD (completely knock down condition) and then fixed/jointed at the site and raised with the help of cranes.

Pre Engineered Buildings Steel Buildings, Steel Structure LinkedIn

We create pre-engineered metal buildings for those who look at everything as an opportunity to build. For nearly 120 years, the name Butler Manufacturing ™ has been synonymous with innovation. We pioneered the metal building industry in 1901 by challenging the status quo and continue to deliver innovative and versatile solutions to our.

When is a Preengineered Metal Building right for your project? JL Architects

The induction of modern technology in the steel manufacturing industry has enabled designers to get the desired control over the steel section shapes and profiles resulting in efficient use of construction material and manufacturing energy required to produce these materials.

PreEngineered Steel Structure Chuan EU Steel Products Supplier Singapore

Description. A Pre- Engineered Building or PEB is a metal building frame that includes a structural system and often also roof and wall cladding. A PEB building, as it is called, is engineered at a factory and assembled at site. Built-up sections are fabricated at the factory to size and then transported to site to assemble with bolted connections.