Quartz Stone How Is It Processed and What Is It Good for? Fote Machinery

Quartz vs. Granite Countertops Which Is Best? (2024 Guide) Forbes Home

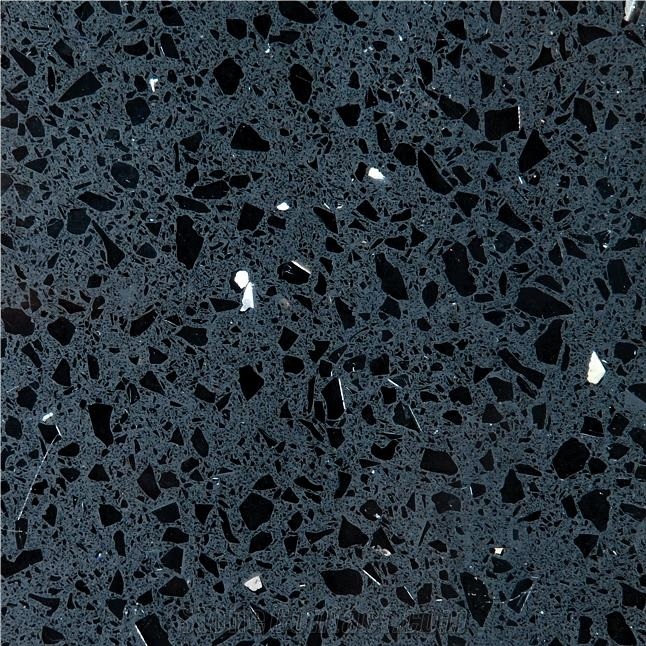

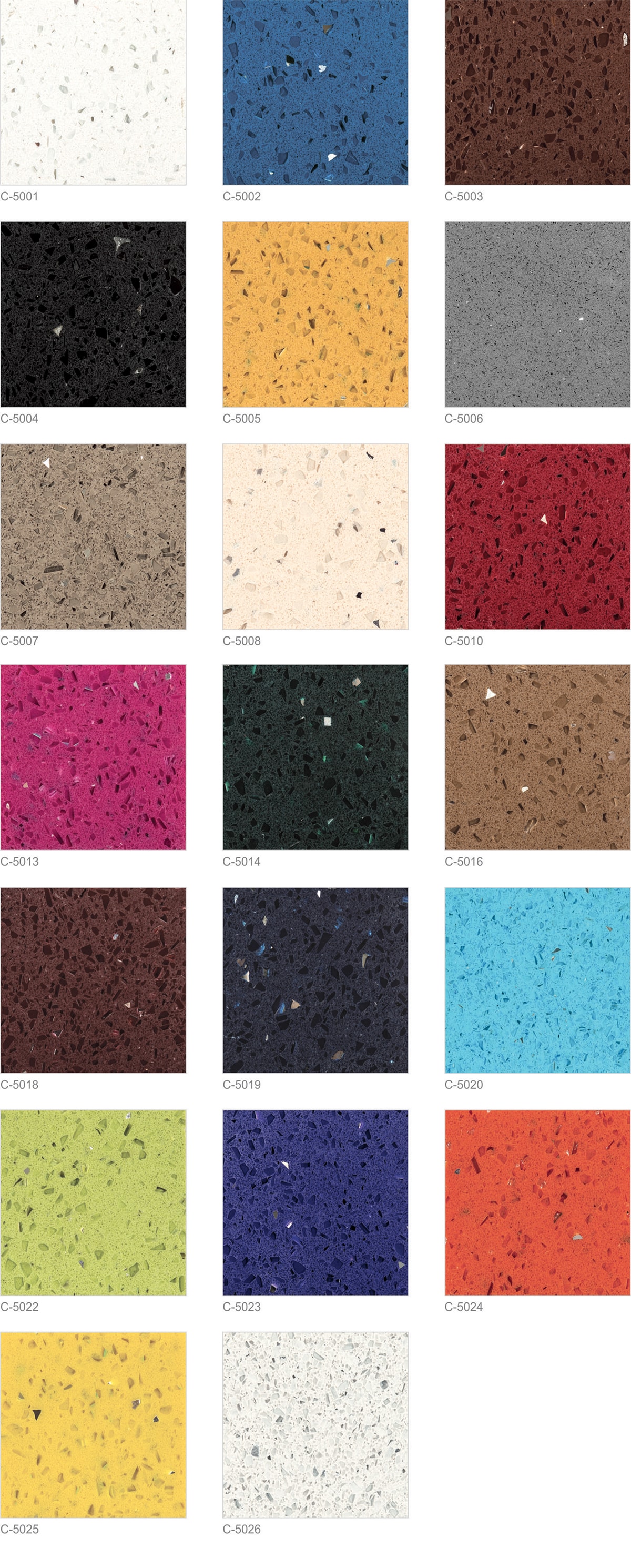

The Advantages of Engineered Quartz #1: Finishes. Engineered quartz comes in a variety of finishes and colors, making it stress-free to decide what works best for your taste and palette. You can pick from a variety of options such as speckles or veining that mimic natural stone countertop or a solid color. Several engineered quartz selections look so similar to authentic stone that it is hard.

Quartz Stone,Engineered Stone,Quartz Countertophej from China

How quartz is made. Quartz can be found almost everywhere. The whole process of your quartz countertop begins when the clusters of the stone are extracted from the ground. The quartz is crushed and then combined with different elements such as polyester resins and pigments. After the mix, this combination will be compacted into slabs.

Quartz Countertops Pros And Cons (2024 Guide) Forbes Home

Engineered Stone vs Granite. As we all know, engineered stone is made from 90 percent quartz and the rest is resins and polymer. The natural stone crystals are blended and heated to create the surface of the engineered stone. Granite, on the other hand, is a natural stone. It is best to use for high-end projects.

Large Smokey Quartz Elestial

You know the debate - natural stone can be gorgeous (and expensive), but it can stain, show wear and tear, and many people can't stand the aged look (including my brother and SIL). Engineered stone (Quartz) is highly durable and easy to clean but has less "real" looking movement to it.

Quartz Crystal Mineral Specimen Celestial Earth Minerals

Most engineered stones are fantastic for high-wear uses such as kitchen countertops . The types and sizes of the components used to make the engineered stone that will determine its best uses. An.

Benefits of Using Engineered Quartz or Quartz ManMade Quartz

Q Stone (MSI Quartz) Q Stone is a quartz product made by MSI Surfaces. They boast a range of collections made to mimic the look of natural stone, including Marble Looks, Natural Looks, and Limestone Looks. Warranty: Q stone products come with a residential lifetime warranty. Care and cleaning: Use a soft sponge and water for most spills.

Free photo Quartz crystal Crystal, Quartz, Stone Free Download

Engineered quartz is made by mixing ground stone and resins, plus pigments, to create slabs of material. Most engineered slabs blend 90 to 94 percent ground quartz with 6 to 10 percent resins. Engineered quartz slabs are not made to order, and the manufacturer creates slabs of set sizes and thicknesses. The slabs are made to fit a specific.

Engineered quartz stone slab BC5003

Quartz is an affordable substitute for other natural stones. An engineered stone countertop usually costs around $60 to $120 per square foot. The price will likely increase based on the brand, color, design pattern, slab thickness, and personal modifications.

Engineered Quartz Stone Suresh 'N' Suresh

Quartz Content: Engineered Stone vs. Granite. Engineered Stone: Typically contains over 90% quartz, making it highly durable but also a significant source of silica dust. Granite: A natural stone, granite contains between 20% to 60% quartz, depending on the variety. This lower quartz content results in less silica exposure during processing.

3 LARGE Clear Quartz Points Crystals Large 1 to 1.5 (Crystal Points

Engineered Stone Countertops are Very Attractive. The quartz material is compressed into slabs that have similar color and texture to natural granite and slate. One difference you'll notice is that the color is more uniform. Engineered Stone Countertops. than the variations in hue you'll find in most slabs of natural stone.

FileQuartz oisan.jpg Wikipedia

Slightly more affordable than premium natural stone and comparable to medium-range granite, engineered quartz generally costs between $70 and $120 per square foot installed. Price variations depend on color choice, configurations, and your location. And, as with natural stone, don't overlook the availability of remnants.

Engineered quartz discover its power for decoration

Engineered quartz comes in a multitude of colors, making it easy to find an option that works with your palette. You can pick a solid color or an option with speckles or veining that imitates natural stone. Some engineered quartz options "look so much like an authentic stone these days without the hassle of maintenance and cost," Forteza says.

Natural Stone vs. Engineered Stone Countertops Understanding the

What is Engineered Stone? Engineered stone, often referred to in the countertop industry as quartz, is a composite material made of crushed stone bound together by an adhesive. It has many different applications. In the case of counters, slabs are made from quartz crystals held together with a resin binder.

Clear Quartz Crystal Moroccan Quartz Geode / Healing Crystals

Unlike engineered stone, solid-surface countertops are composed primarily of very hard, very durable acrylic. Colorants and particulates in the mixture often resemble stone, but these counters are also offered in varying bright, sometimes translucent colors. Like engineered quartz, this material is non-porous and easy to maintain.

1894g Clear Quartz Crystal Cluster Large Specimen with Double

Quartz countertops are easy to clean and maintain. All that is needed to clean engineered stone countertops is warm water and mild soap. And for stubborn spills, non-abrasive cleaners and approved cleaners are all that is needed. If dealing with dried spills, re-animate with water for a few minutes and clean with a damp towel.

Engineered Quartz Options Delivery Stone

Quartz countertops are man-made products. Manufactured quartz countertops do contain natural quartz, but they are also made up of binding resins. So quartz is considered an engineered material; not a natural stone. This means you don't get the unique, natural veining that can be found in granite and marble.