The Beauty and Benefits of Damascus Steel in Knife Making

/knifemaker-polishing-a-damascus-steel-blade-151186351-5793b3c55f9b58173bb4c542.jpg)

Damascus Steel Ancient Sword Making Techniques

Many of the strength benefits of Damascus steel come from its carbon content. Carbon steel has properties that make knife blades hard and durable, which allows them to hold an edge and be razor-sharp.. Damascus steel should have however many layers of carbon steel and stainless steel that it takes to produce the look and quality you desire.

Damascus Patterns knives, Knife patterns, Blacksmithing knives

Damascus steel is a type of steel that has a long history in the Middle East. It is believed to have been first created in Damascus, Syria, and that is where it gets its name. Damascus steel is made by combining different types of metal alloys, and the end result is a blade that is both durable and sharp. Damascus steel contains carbon and.

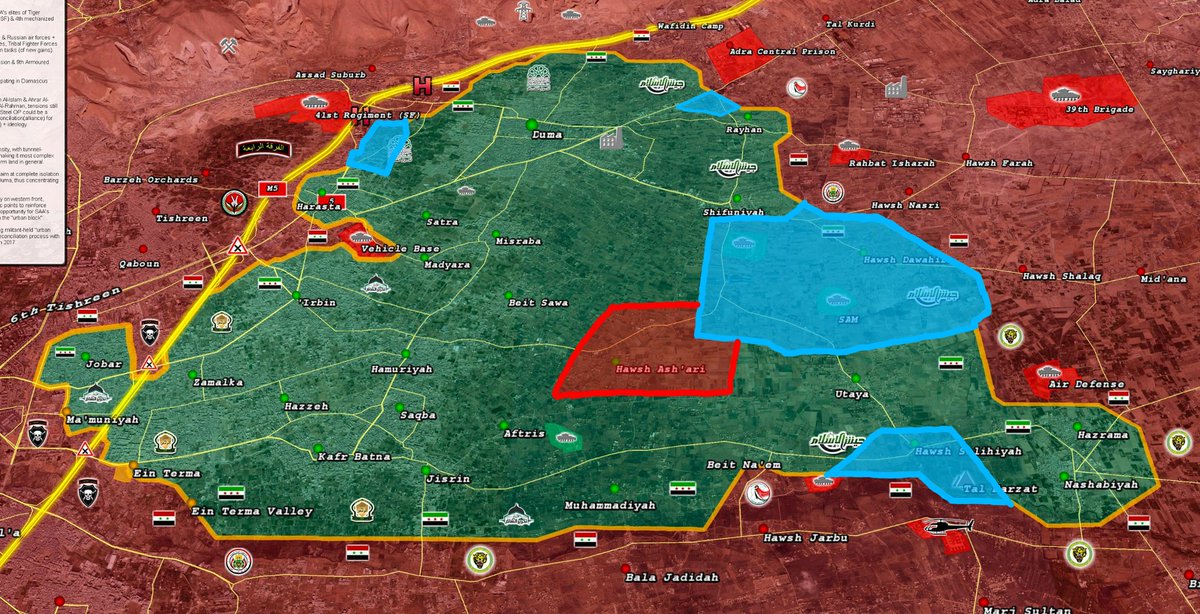

Gains by SAA since starting the Damascus steel offensive r/syriancivilwar

Damascus steel knives are more than just visual: they bring superior cutting power on top of improved edge retention, better corrosion resistance than mono high carbon stainless steel, and aesthetic appeal. These knives are also relatively easier to hone and sharpen, while they wear away more uniformly to improve durability.

Damascus steel the metal used to some of the world's

Some high-quality Damascus knives can fetch $5,000 and up, taking at least a month to create. A video featuring master bladesmith Zack Jonas explains how he stacks multiple layers of high-carbon steel and heats them to about 2,300 degrees Fahrenheit in the forge. Bolder patterns require fewer layers, while very intricate ones potentially need hundreds or thousands of layers.

Benefits of Damascus Steel Kefi Mind

Damascus steel was made from a combination of Wootz steel and particular forging techniques that have been lost through the sands of time. From the 3 rd and 4 th centuries and all the way to the 18 th century, Damascus steel was known for being perhaps the best type of steel for blades and knives.. Sadly, these special forging techniques were lost, as was the Wootz steel.

The Ultimate Guide To Damascus Steel HiConsumption

The history of Damascus steel (Damask, alternatively) actually dates back centuries - as far as the 400s CE to be precise. And though, in one way or another, it derives its name from the Syrian capital city, the steel that Damascus is crafted from doesn't come from Syria or the Middle East at all. In fact, it was imported from either India.

The Ultimate Guide to Understanding Damascus Knives What They Are and

The final secret to old-fashioned Damascus steel comes not from the weird quenching rituals or the crucible that produced the ingots. Nope, it comes from the way it was heated. Wootz, according to one Dr. Wadworth (awesome name, by the way), was processed at temperatures as high as 2,300 degrees.

Custom made Damascus Steel Skinner Knife Damascus Blades

It's made for a purpose. Because of the forging technique used to create Damascus steel, the finished product (the knife you're looking to buy) is likely a high-quality, highly useful tool. That's because the creator of the Damascus steel selected the alloys that would best work together for the purpose at hand - and would create a.

History of damascus steel a thing of beauty by williamhenry Issuu

Today, blacksmiths make Damascus by welding different types of steels together and working them into folded layers. Depending on the steels included in the mix, the final product will exhibit different qualities. The process is rigorous and hands-on and as such, most Damascus steel comes from the workshops of craftsmen like Devin Thomas, Chad.

Damascus Steel A Steel Unlike Any Other Glimpse by GRAY®

Birchwood: Our favorite is the Miyabi Birchwood, with an HRC of 63 and 100 layers of Damascus steel overlay protecting it. About $300 for an 8-inch chef knife. Miyabi Black chef knife. Black: If you want to move up a notch, the Miyabi Black has astonishing HRC 66 and 133 layers of Damascus steel overlay.

What Are The Benefits Of Damascus Steel

The heating treatment for Damascus steel involves a preset temperature between 1,500F and 2,000F, depending on the banding, and a mixture of both cementite and austerntite. Preset furnace temperature accordingly. Set metal block in the furnace. Heat through its cycle to its starting temperature.

What is Damascus Steel? F.N. Sharp

Damascus steel originally referred to swords made from wootz, a high-carbon steel created about two thousand years ago. The blades were regarded for their strength, flexibility, and ability to retain a keen edge, as well as the distinct water-like pattern of the metal. The original forging practice died out over time, but we still use Damascus.

Is Damascus Steel Good? Choppy Choppy

What Is Damascus Steel? Damascus steel has been around since before the time of Alexander the Great in the 300s B.C., originating with the production of wootz steel in India, which had impurities from being made in a high-temperature crucible. As this steel spread, it was forged into weapons notable for their unique watery bands as well as.

Best Wholesale Damascus Steel Bread Knife Distributor + Bulk Discounts

Damascus steel has a Rockwell hardness of between 30-50, depending on the particular composition of the ingots used. However, even a basic kitchen knife today has a Rockwell hardness in the mid-50s. Furthermore, most blades made today are stainless steel, meaning that they are far more resistant to corrosion and highly durable, an advantage.

The Beauty and Benefits of Damascus Steel in Knife Making

What is Damascus steel? Damascus steel is one solid piece of steel made from layering two different alloys — 1080 high-carbon steel and 15N20 carbon steel, for instance. You can't make Damascus steel by combining two pieces of the same alloy. That would be like stacking red Play-Doh on top of red Play-Doh — you just end up with red Play-Doh.

What’s the Deal with Damascus Steel? Cool Material

The second benefit to damascus blade steel is the combination of low and high carbon steel allows the low carbon steel to wear out a bit quicker leaving the high carbon intact. This in turn creates small microscopic serration which may provide faster cutting. However this cutting wont be as smooth as a sharp fine edge with no serrations.